Advancing responsible sourcing

in mineral value chains

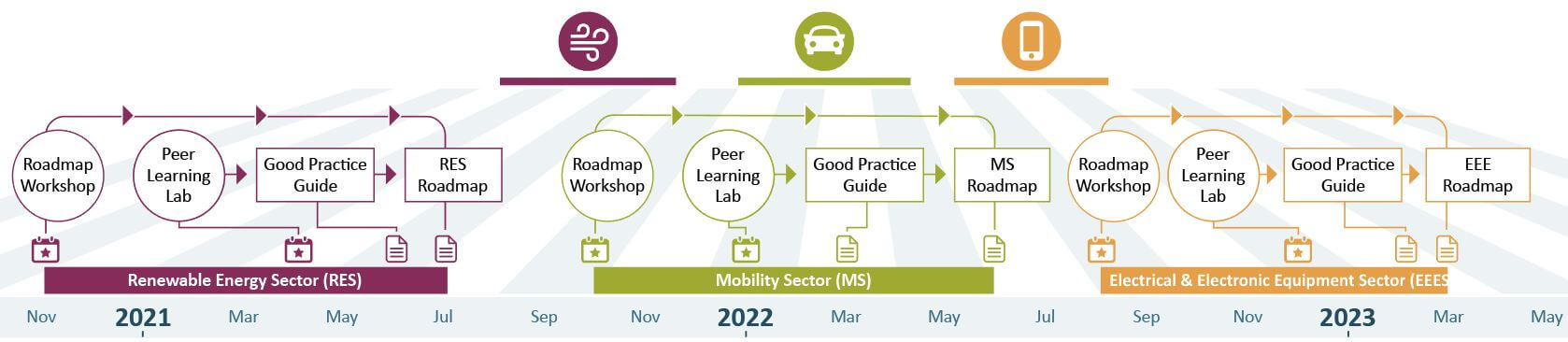

The RE-SOURCING project is an EU-funded Multi-Stakeholder Platform that aims to advance Responsible Sourcing of raw materials along and across global mineral value chains. It strives to promote both strategic agenda setting and coherent application of practices for Responsible Sourcing. 12 partners aim at developing criteria for a responsible sourcing definition. The project focuses on three sectors: Renewable Energy, Mobility and Electronics. For more details please see the Sectors page.

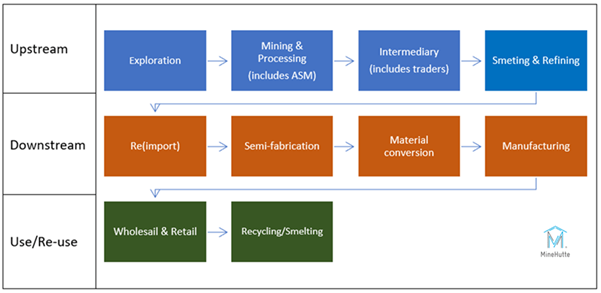

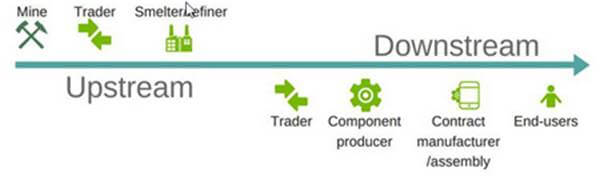

A supply chain is a process for mapping the movement of goods and services, it is devoid of the power relations that exist between the firms in a chain. A value chain on the other hand notes where ‘value’ is created along the supply chain – which firms have the power of design, governance, standard setting, procurement guidelines, auditing control, financial control etc. This project considers three stages of the value chain:

Upstream: Refers to the extraction process and includes exploration, mining and processing, intermediary and export of minerals. Smelters and refineries are included in this segment of the chain.

Downstream: Refers to (re)import, semi-fabrication, material conversion and manufacturing.

Use/Re-Use Phase: Wholesale and retail, recycling/smelting are included as a third segment, for this project. This allows for an evaluation of RS practices specific to the recycling node of the chain.

For more details on the project approach please see The RE-SOURCING Common Approach.

The renewable energy sector includes a host of sources, with 91% of the energy generation coming from biomass, hydropower and wind (2017). Solar energy remains an important source of renewable energy for the future. The EU target, under the revised Renewable Energy Directive, is set at 32% energy from renewable energy sources by 2035. The RE-SOURCING project focuses on the mining & processing stage and the manufacturing stages of the value chain in the renewable energy sector.

For detailed information, please see RE Sector or the State-of-play Report on Renewable Energy.

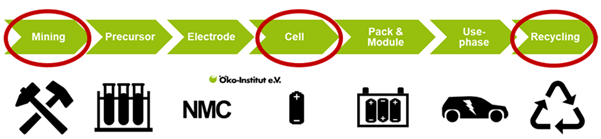

The mobility sector is one of the largest manufacturing sectors in the EU. In 2017, the transport sector also accounted for 25% of the EU28 GHG emissions. Therefore, the main elements of the European Strategy for Low-emission Mobility include speeding up the deployment of low-emission alternative energy for transport and moving towards zero-emission vehicles. A key strategy for this shift to be successful is the transition to Hybrid and Electric Vehicles; in 2050, 80% of all newly registered passenger cars globally could be powered by alternative drivetrains. The key to e-mobility is the production of strong, efficient and affordable batteries. In the value chain of electric cars, the battery is the most valuable component with a share of 40% of value. The mobility sector will focus on the more mature technology of the electric battery, which will be the key component of the sustainability transition agenda in the EU.

The focus of the research in the RE-SOURCING project is on three nodes within this value chain: the mining of selected minerals; cell manufacturing and recycling.

Focus within the relevant battery materials is on lithium, cobalt, nickel and graphite.

For further information on the mobility sector please see Mobility Sector or the State of Play Report on the Mobility Sector.

The Electronics sector is one of the largest industries in the world, with approximately 18 million workers, producing 20% of global imports and $1.7 trillion in trade in electronics products. It is a major contributor to creating economic growth and opportunities across the world and is key for many industries (automotive, healthcare, aeronautics, space, communications).

The EEE Sector covers many products from electronic components and boards; computers and peripheral equipment; consumer electronics, electronic and electric wires and cables.

The range of materials used in EEE products is relatively extensive. The research focus in the project will be on:

3TG (Tin, Tungsten, Tantalum, Gold): They have high relevance due to legislation (OECD, EU, Dodd-Frank) that govern responsible sourcing practices and have high industry consumption and function criticality (tin, tantalum) for EEE products.

Mica: Has high relevance within the EEE and the mobility sector, with severe sustainability risks associated with its extraction.

For further details please see EEE Sector or The State of Play Report for the EEE Sector

.

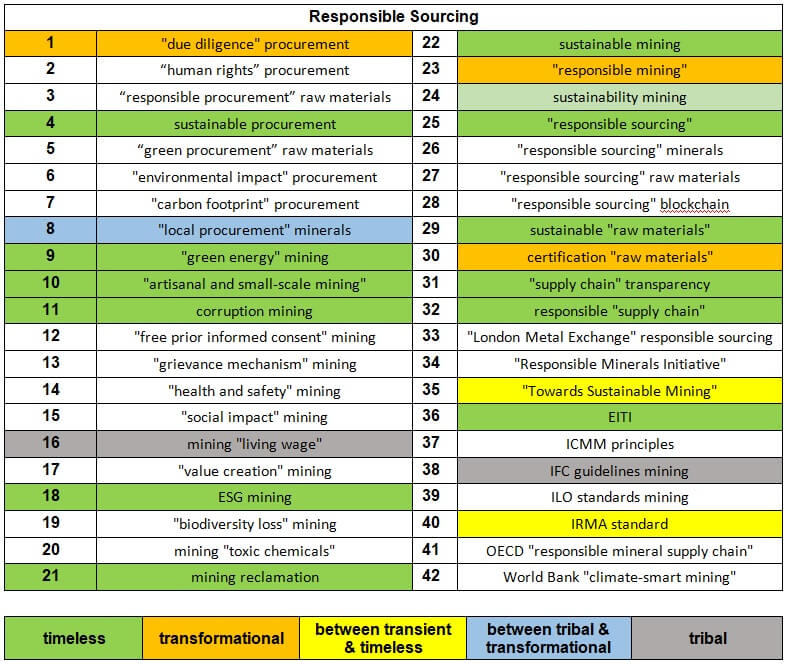

The RE-SOURCING project conducted a narrative analysis in autumn 2020 on the overall issue of responsible sourcing and on three sectors in the focus of the project: renewable energy, mobility and electronic and electric equipment. The results of the narrative analysis of the online discourse addressing responsible sourcing in general and specifically for the renewable energy sector are explained and visualized in the State of Play Report on the Renewable Energy Sector – Chapter 4. The results of the narrative analysis on the mobility sector are available in the State of Play Report on the Mobility Sector – Chapter 5.